[ad_1]

Information briefs for the week check out particular cobot debuts at FABTECH and Pack Expo: Neuromeka’s robotic welding cell for shipbuilding and Staubli’s TX2-60 Stericlean for high-risk sterile environments, the first-ever, mass-produced humanoid robots, a robotic system, after 250,000 tries, discovers hardest identified construction, subsea robots service “floating” wind farm, and Aura, the humanoid “spokesbot” for the brand new Las Vegas Sphere.

Tradeshows debut new cobot duties

FABTECH (Chicago) and Pack Expo (Las Vegas), tradeshows that have been run practically concurrently this previous September 11-14, at all times have a number of surprises showcased for the primary time, and this yr was no completely different. New duties for cobots have been highlighted.

FABTECH

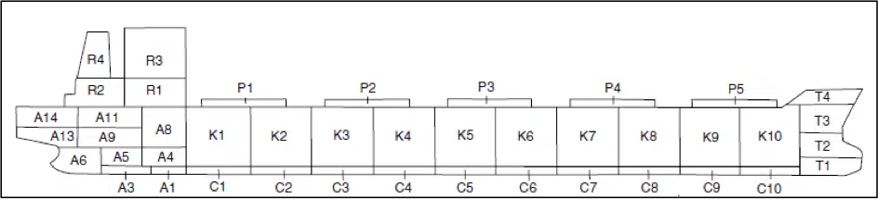

Korea-based Neuromeka launched a brand new robotic welding cell at FABTECH’s robotic pavilion. The cobot welding cell is particularly designed for block welding processes within the building of huge ships. Blocks check with a ship’s hull which is split into sections known as blocks (see diagram).

Every block is once more divided into assemblies and sub-assemblies. These are welded collectively to kind three-dimensional constructions known as block assemblies.

Neuromeka’s cobot block-welding cell options arc sensor-based welding, seam monitoring, and computerized detection of welding irregularities utilizing 3D cameras.

Its user-friendly interface and simplified programming lend themselves effectively to non-expert use, which is interesting to shipbuilding’s present labor shortage.

Pack Expo

Swiss-based Stäubli showcased its high-precision TX2-60 Stericlean robotic that automates medical gadget manufacturing processes  and is designed for high-risk sterile environments.

and is designed for high-risk sterile environments.

The TX2-60 picks and locations medical gadget parts utilizing AI imaginative and prescient to find applicable components after which transmits their decide coordinates to the robotic for the pick-and-place maneuver. Manufacturing is tracked by the use of a monitor, permitting full traceability, whereas each operational security and effectivity are maintained.

The 6-axis, TX2-60 Stericlean is designed to satisfy the “stringent necessities of hydrogen peroxide (H²O²) decontamination course of.” It could actually function in a Grade A surroundings (clear room high-risk operations) for numerous functions in laboratory, batch testing, or pharmaceutical manufacturing.

Each the Neuromeka welding cell and the Staubli Stericlean spotlight the capabilities and flexibility of cobots in taking over beforehand handbook duties, which yearly appears to be the evolving hallmark of cobot know-how.

First-ever, mass-produced humanoid robots

Mass-producing a robotic at scale whose know-how is developed sufficient to belief is what all robotic distributors aspire to. Mass manufacturing of bi-pedal humanoid robots has, till lately, by no means been tried. …Not any longer!

Oregon-based Agility Robotics is constructing a manufacturing facility able to producing 10,000 of its humanoid robotic Digit. A primary-ever for bi-pedal humanoids.

Oregon-based Agility Robotics is constructing a manufacturing facility able to producing 10,000 of its humanoid robotic Digit. A primary-ever for bi-pedal humanoids.

“The opening of our manufacturing facility marks a pivotal second within the historical past of robotics: the start of the mass manufacturing of economic humanoid robots,” mentioned Agility Robotics’ co-founder and CEO Damion Shelton.

The market seems to be prepared. Extremely, humanoid robots at present at a $1.8 billion international market is forecast to blow up to $13.8 billion by 2028, with a compound annual progress fee (CAGR) of fifty%!

Traders are onboard: 2022 noticed Agility decide up $150 million from Amazon and others.

With confidence ranges seemingly sky excessive, the startup (based in 2015; offered its first Digits in 2018) is constructing a manufacturing facility in Salem, Oregon that it calls a RoboFab. If and when it will get to max manufacturing of 10,000 robots yearly, the 70,000-square-foot facility will make use of 500, says the corporate.

Shelton advised CNBC that his staff developed Digit with a human kind issue in order that the robots can carry, type, and maneuver whereas staying balanced, and so “they may function in environments the place steps or different constructions might in any other case restrict the usage of robotics. The robots are powered with rechargeable lithium-ion batteries.”

Because the firm web site places it: “You don’t accomplish “by no means been finished earlier than” with no tradition that helps risk-taking and wholesome residing.”

Video: Evolution of Digit 2015 to 2023:

The brand new manufacturing facility: RoboFab:

Robotic discovers hardest identified construction

It took a 6-axis robotic and its lab mates—5 3D printers, a scale, and a common testing machine—to work by 25,000 lab experiments earlier than discovering the world’s hardest new construction. At a fee of fifty experiments per day, all of the experiments have been  carried out in a completely autonomous robotics laboratory with none human supervision.

carried out in a completely autonomous robotics laboratory with none human supervision.

A product of Boston College’s School of Engineering, The novel construction, dubbed Willow, is fabricated from a sort of polyester known as PLA and measured 73.3% vitality absorption. Because the 5 3D printers use seven kinds of plastic to create completely different constructions, the constructions are analyzed for his or her energy-absorption capabilities utilizing a compression machine and a pc imaginative and prescient system to watch the responses. The 6-axis cobot arm strikes plastic samples for testing.

By brute testing by 25,000 experiments, the system discovered Willow, the hardest construction ever recorded. The findings, in line with the researchers, characterize a possible sport changer in designs throughout industries, bettering security in automobiles, in addition to helmets and different protecting tools for numerous sports activities.

For the robotic system, it represents a bigger image as a result of autonomous analysis and discovery with the robotic system doing the lab work completely, is a brand new pattern that saves lab employees from repetitive drudgery and but opens up alternatives to make new discoveries like Willow.

Subsea robots service “floating” wind farm

When ocean wind farms can’t set down pillars for stability on the seabed, they then have to float on the floor, which might trigger a number of issues.

Norwegian vitality large Equinor received a 2-gigawatt (GW) lease in Morro Bay, California, for America’s first-ever offshore wind lease to assist commercial-scale “floating” offshore wind improvement. By way of energy output, the Moro Bay Venture has the potential to generate sufficient vitality to energy round 750,000 US households.

Norwegian vitality large Equinor received a 2-gigawatt (GW) lease in Morro Bay, California, for America’s first-ever offshore wind lease to assist commercial-scale “floating” offshore wind improvement. By way of energy output, the Moro Bay Venture has the potential to generate sufficient vitality to energy round 750,000 US households.

Deploying to Morro Bay in February 2024, Equinor has contracted with marine robotics firm Austin, TX-based Ocean Infinity to conduct a website investigation survey utilizing a number of AUVs (autonomous underwater automobiles).

Shawntel Johnson, director of enterprise improvement at Ocean Infinity, mentioned, “AUVs in scale are the right instrument for the US West Coast, offering not solely nice knowledge high quality benefits over towed arrays, in water depths right down to 4,000 toes but in addition enormous effectivity over huge areas.”

In keeping with Equinor, The info that the AUVs accumulate will assist Equinor develop and refine its floating offshore wind farm design and also will help in creating the location evaluation, plus building and operations plans.

Humanoid robotic Aura awaits you in Las Vegas

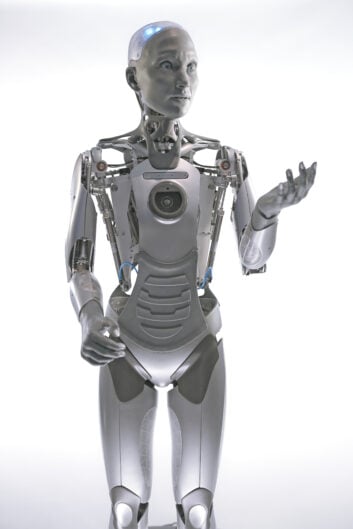

We’ve seen the face of Aura earlier than, haven’t we?

The brand new and large Las Vegas Sphere (giant sufficient to simply match all the 151-foot tall Statue of Liberty, is quickly to open because the world’s largest leisure venue (music, reveals, motion pictures, and so on.)

Thumbnail of Sphere: “The spherical, a 366-foot-high venue positioned simply off the Las Vegas strip has 17,600 seats and might maintain as much as 20,000 individuals. The skin, referred to as the Exosphere, is roofed in 1.2 million programmable LEDs that may be seen from as much as a mile away.”

Thumbnail of Sphere: “The spherical, a 366-foot-high venue positioned simply off the Las Vegas strip has 17,600 seats and might maintain as much as 20,000 individuals. The skin, referred to as the Exosphere, is roofed in 1.2 million programmable LEDs that may be seen from as much as a mile away.”

Inside the Sphere, and billed as a “spokesbot”, is Aura the humanoid robotic, in addition to 4 different clones of herself. The robots will help guests with instructions and knowledge, and in addition give background concerning the Sphere to anybody who asks.

Aura is the robotic we’ve seen earlier than; the male model of Aura known as Ameca debuted at CES2022 (Las Vegas) by UK-based Engineered Arts.

He/she is again once more in Las Vegas for a everlasting position as Aura the spokesbot for the Sphere.

“We’re pushing the boundaries of how robotics can be utilized to boost our visitors’ journey by the venue,” mentioned David Dibble, CEO of MSG Ventures, a division of Sphere Leisure. Aura is designed to work together with visitors and can function a “spokesbot” for Sphere on digital and social platforms.

Right here’s a glimpse of the Sphere and Aura:

Right here’s a backgrounder on robotics, engineered Arts & Ameca:

![]()

[ad_2]