[ad_1]

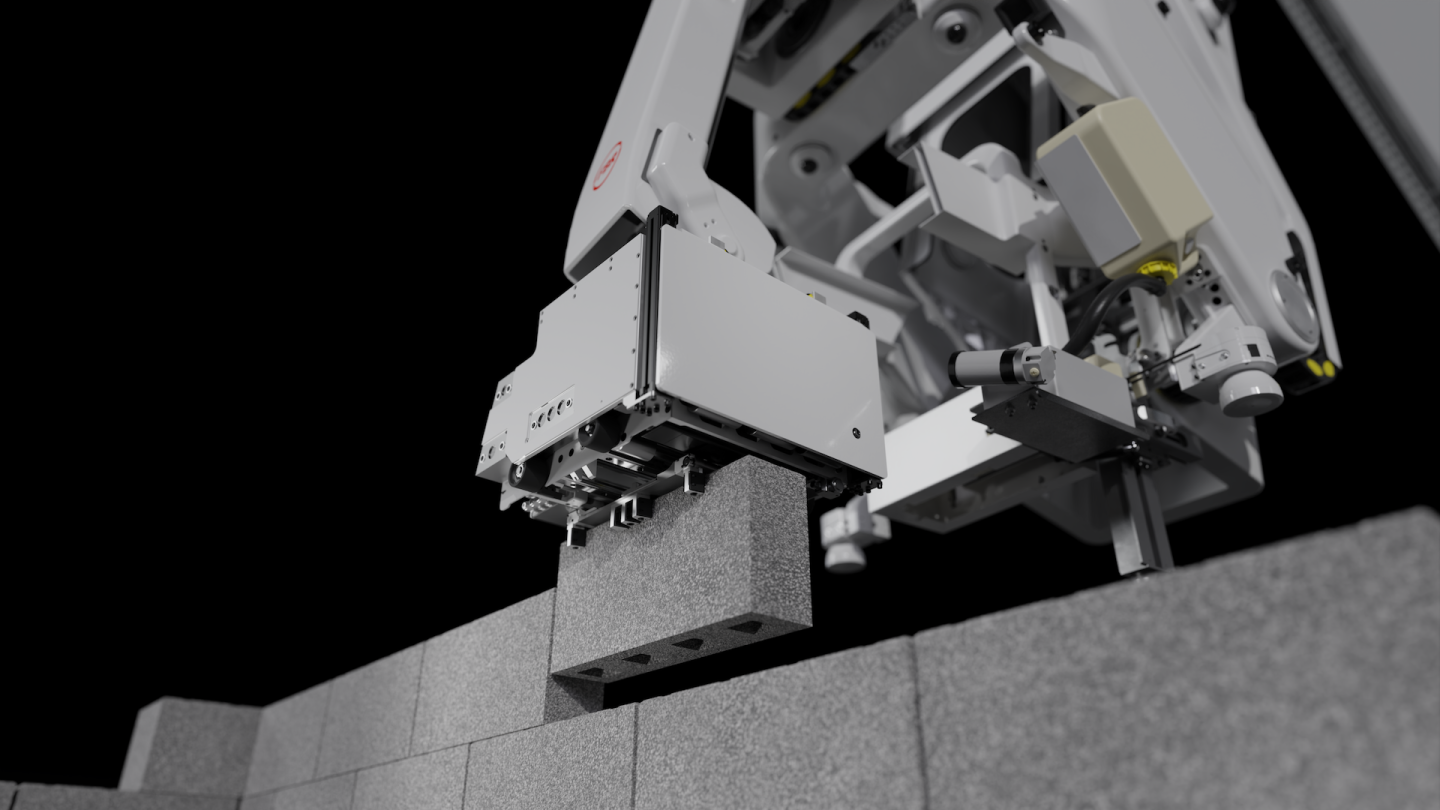

The extraordinary Hadrian X bricklaying robotic rocks as much as a constructing website trying like a daily truck, then extends a 32-m (105-ft) growth arm and begins exactly laying as much as 300 giant masonry blocks an hour. It is fairly exceptional to look at.

We have had our eye on this Australian bot because it was an excavator-mounted prototype again in 2015. Even then, it was able to laying the brick framework for a full-sized dwelling in about two days – some 20 instances sooner than human bricklayers, in response to Fastbrick Robotics, now generally known as FBR and the creator of the robotic.

Now, in 2023, it is beginning to roll out commercially. FBR has constructed its first “subsequent gen” Hadrian-X system, and final month it set a brand new pace file on its first outside take a look at construct, demonstrating a sustained fee over 300 USA-format masonry blocks per hour on a testing and calibration run.

Extrapolate that fee to the most important blocks it may well deal with – 45-kg (99-lb) monsters measuring 600 x 400 x 300 mm (23.6 x 15.7 x 11.8 in) and also you’re taking a look at a machine able to placing down some 70 sq m (753 sq ft) of vertical wall each hour – that is a couple of quarter of a tennis court docket. Oh, and FBR truly expects it to get rather a lot sooner; its rated high pace is 500 blocks per hour.

FBR

Arriving on website, the Hadrian X is operated by pill, and can lay bricks with precision in response to a CAD plan. Staff feed masonry blocks into the again of the truck by the pallet load, whereupon “dehacker” robots unpack them and reduce them to measurement if mandatory utilizing a round noticed.

Then they’re despatched one after the other down the center of the growth arm on little shuttles, painted with a particular building adhesive instead of mortar, and laid down in place, the place they’re dry and safe inside 45 minutes.

Hadrian X® – The Way forward for Robotic Development

The Hadrian X’s telescoping growth arm is lengthy sufficient to construct three-story buildings from road stage with no ladder to be seen, and it may well work 24/7, apparently underneath most climate situations.

As for the ultimate outcome, properly, FBR’s first outside take a look at construct as proven within the video beneath may lead to some harsh phrases from an employer – have a look across the 1:08 mark, the place the lighting exhibits some clear inaccuracies in brick placement. However provided that this was actually the primary testing and calibration run for the next-gen robotic, we’ll assume that is not more likely to stay an issue for lengthy.

FBR

FBR has second and third robots underneath building, and the primary and second will quickly be despatched to the USA to run demonstrations, and to get straight to work in FBR’s Florida-based “Wall as a Service” enterprise.

Try the record-breaking first take a look at of the brand new system beneath.

Subsequent-Gen Hadrian X® completes first outside take a look at construct | FBR

Supply: FBR

[ad_2]