[ad_1]

And not using a map, it may be nearly inconceivable to know not simply the place you’re, however the place you’re going, and that’s very true in the case of supplies properties.

For many years, scientists have understood that whereas bulk supplies behave in sure methods, these guidelines can break down for supplies on the micro- and nano-scales, and sometimes in stunning methods. A kind of surprises was the discovering that, for some supplies, making use of even modest strains — an idea often known as elastic pressure engineering — on supplies can dramatically enhance sure properties, supplied these strains keep elastic and don’t loosen up away by plasticity, fracture, or part transformations. Micro- and nano-scale supplies are particularly good at holding utilized strains within the elastic type.

Exactly how you can apply these elastic strains (or equivalently, residual stress) to realize sure materials properties, nevertheless, had been much less clear — till just lately.

Utilizing a mixture of first rules calculations and machine studying, a group of MIT researchers has developed the first-ever map of how you can tune crystalline supplies to provide particular thermal and digital properties.

Led by Ju Li, the Battelle Vitality Alliance Professor in Nuclear Engineering and professor of supplies science and engineering, the group described a framework for understanding exactly how altering the elastic strains on a fabric can fine-tune properties like thermal and electrical conductivity. The work is described in an open-access paper revealed in PNAS.

“For the primary time, by utilizing machine studying, we’ve been in a position to delineate the entire six-dimensional boundary of preferrred energy, which is the higher restrict to elastic pressure engineering, and create a map for these digital and phononic properties,” Li says. “We will now use this strategy to discover many different supplies. Historically, individuals create new supplies by altering the chemistry.”

“For instance, with a ternary alloy, you possibly can change the share of two parts, so you’ve two levels of freedom,” he continues. “What we’ve proven is that diamond, with only one aspect, is equal to a six-component alloy, as a result of you’ve six levels of elastic pressure freedom you possibly can tune independently.”

Small strains, massive materials advantages

The paper builds on a basis laid way back to the Eighties, when researchers first found that the efficiency of semiconductor supplies doubled when a small — simply 1 % — elastic pressure was utilized to the fabric.

Whereas that discovery was shortly commercialized by the semiconductor business and right this moment is used to extend the efficiency of microchips in all the things from laptops to cellphones, that stage of pressure may be very small in comparison with what we will obtain now, says Subra Suresh, the Vannevar Bush Professor of Engineering Emeritus.

In a 2018 Science paper, Suresh, Dao, and colleagues demonstrated that 1 % pressure was simply the tip of the iceberg.

As a part of a 2018 examine, Suresh and colleagues demonstrated for the primary time that diamond nanoneedles may stand up to elastic strains of as a lot as 9 % and nonetheless return to their unique state. In a while, a number of teams independently confirmed that microscale diamond can certainly elastically deform by roughly 7 % in stress reversibly.

“As soon as we confirmed we may bend nanoscale diamonds and create strains on the order of 9 or 10 %, the query was, what do you do with it,” Suresh says. “It seems diamond is an excellent semiconductor materials … and one in all our questions was, if we will mechanically pressure diamond, can we cut back the band hole from 5.6 electron-volts to 2 or three? Or can we get all of it the way in which all the way down to zero, the place it begins to conduct like a steel?”

To reply these questions, the group first turned to machine studying in an effort to get a extra exact image of precisely how pressure altered materials properties.

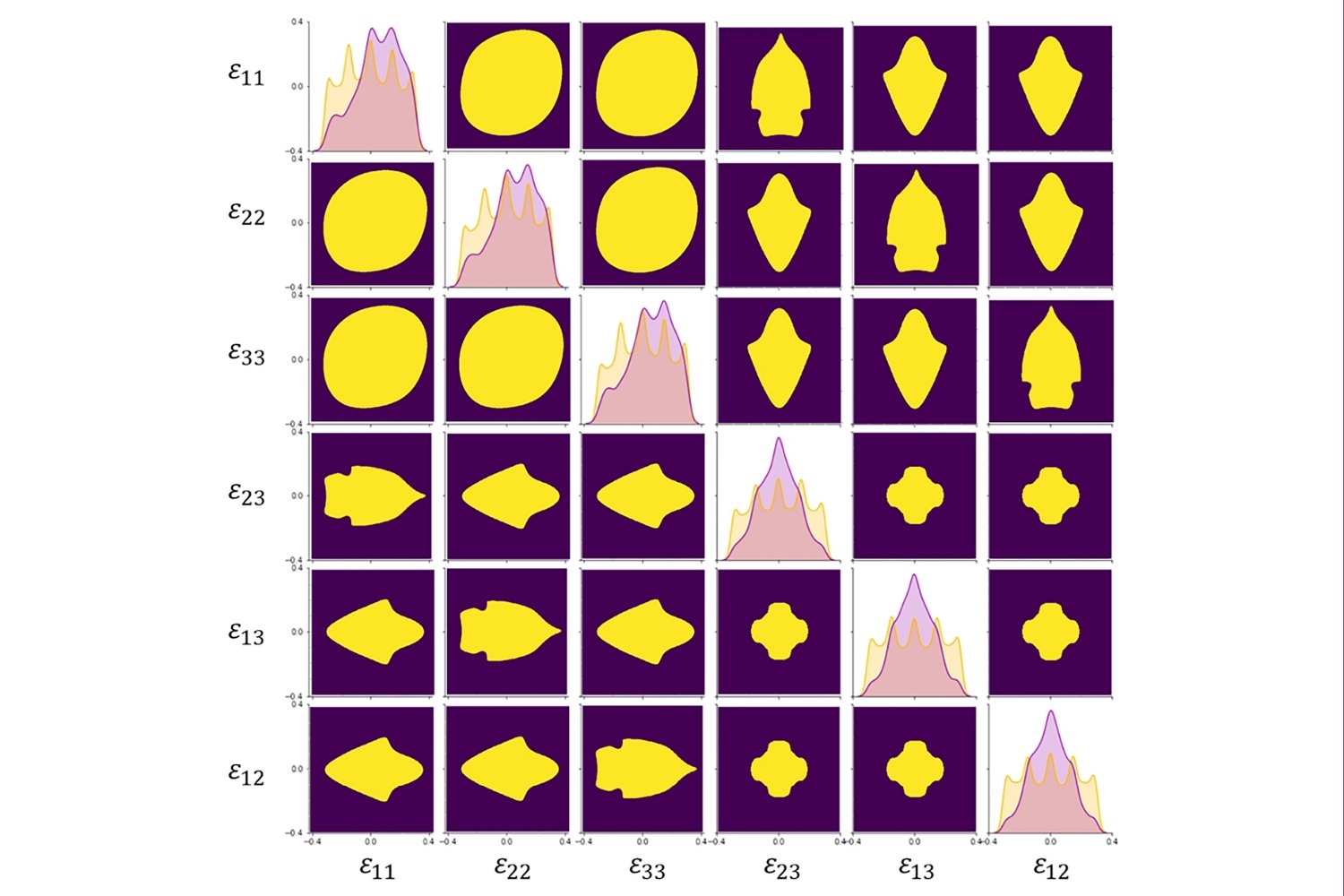

“Pressure is a giant house,” Li explains. “You possibly can have tensile pressure, you possibly can have shear pressure in a number of instructions, so it’s a six-dimensional house, and the phonon band is three-dimensional, so in whole there are 9 tunable parameters. So, we’re utilizing machine studying, for the primary time, to create a whole map for navigating the digital and phononic properties and establish the boundaries.”

Armed with that map, the group subsequently demonstrated how pressure may very well be used to dramatically alter diamond’s semiconductor properties.

“Diamond is just like the Mt. Everest of digital supplies,” Li says, “as a result of it has very excessive thermal conductivity, very excessive dielectric breakdown strengths, a really massive provider mobility. What we’ve got proven is we will controllably squish Mt. Everest down … so we present that by pressure engineering you possibly can both enhance diamond’s thermal conductivity by an element of two, or make it a lot worse by an element of 20.”

New map, new purposes

Going ahead, the findings may very well be used to discover a number of unique materials properties, Li says, from dramatically decreased thermal conductivity to superconductivity.

“Experimentally, these properties are already accessible with nanoneedles and even microbridges,” he says. “And we’ve got seen unique properties, like lowering diamond’s (thermal conductivity) to just a few hundred watts per meter-Kelvin. Just lately, individuals have proven that you could produce room-temperature superconductors with hydrides in case you squeeze them to some hundred gigapascals, so we’ve got discovered every kind of unique habits as soon as we’ve got the map.”

The outcomes may additionally affect the design of next-generation laptop chips able to working a lot quicker and cooler than right this moment’s processors, in addition to quantum sensors and communication units. Because the semiconductor manufacturing business strikes to denser and denser architectures, Suresh says the power to tune a fabric’s thermal conductivity will probably be significantly necessary for warmth dissipation.

Whereas the paper may inform the design of future generations of microchips, Zhe Shi, a postdoc in Li’s lab and first creator of the paper, says extra work will probably be wanted earlier than these chips discover their manner into the common laptop computer or cellphone.

“We all know that 1 % pressure may give you an order of magnitude improve within the clock pace of your CPU,” Shi says. “There are lots of manufacturing and gadget issues that have to be solved to ensure that this to change into sensible, however I feel it’s positively an incredible begin. It’s an thrilling starting to what may result in important strides in expertise.”

This work was supported with funding from the Protection Risk Discount Company, an NSF Graduate Analysis Fellowship, the Nanyang Technological College College of Organic Sciences, the Nationwide Science Basis (NSF), the MIT Vannevar Bush Professorship, and a Nanyang Technological College Distinguished College Professorship.

[ad_2]