[ad_1]

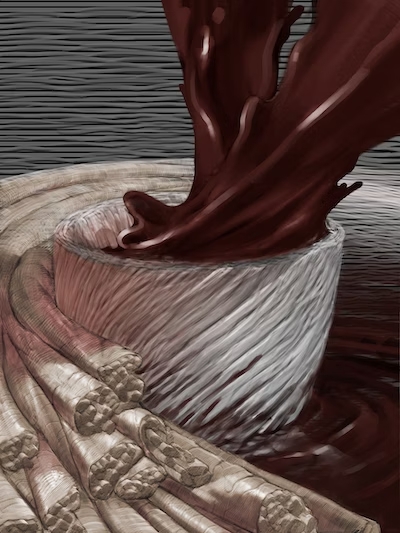

This illustration exhibits a 3D printed coronary heart ventricle engineered with fiber-infused ink. Credit score: Harvard SEAS

By Kat J. McAlpine / SEAS Communications

During the last decade, advances in 3D printing have unlocked new potentialities for bioengineers to construct coronary heart tissues and buildings. Their targets embrace creating higher in vitro platforms for locating new therapeutics for coronary heart illness, the main explanation for demise in the USA, answerable for about one in each 5 deaths nationally, and utilizing 3D-printed cardiac tissues to judge which remedies would possibly work finest in particular person sufferers. A extra distant goal is to manufacture implantable tissues that may heal or substitute defective or diseased buildings inside a affected person’s coronary heart.

In a paper revealed in Nature Supplies, researchers from Harvard John A. Paulson College of Engineering and Utilized Sciences (SEAS) and the Wyss Institute for Biologically Impressed Engineering at Harvard College report the event of a brand new hydrogel ink infused with gelatin fibers that allows 3D printing of a practical coronary heart ventricle that mimics beating like a human coronary heart. They found the fiber-infused gel (FIG) ink permits coronary heart muscle cells printed within the form of a ventricle to align and beat in coordination like a human coronary heart chamber.

“Individuals have been making an attempt to duplicate organ buildings and capabilities to check drug security and efficacy as a approach of predicting what would possibly occur within the scientific setting,” says Suji Choi, analysis affiliate at SEAS and first writer on the paper. However till now, 3D printing methods alone haven’t been capable of obtain physiologically-relevant alignment of cardiomyocytes, the cells answerable for transmitting electrical indicators in a coordinated vogue to contract coronary heart muscle.

“We began this venture to deal with a number of the inadequacies in 3D printing of organic tissues.”

– Kevin “Package” Parker

The innovation lies within the addition of fibers inside a printable ink. “FIG ink is able to flowing by way of the printing nozzle however, as soon as the construction is printed, it maintains its 3D form,” says Choi. “Due to these properties, I discovered it’s doable to print a ventricle-like construction and different advanced 3D shapes with out utilizing additional help supplies or scaffolds.”

This video exhibits the spontaneous beating of a 3D-printed coronary heart muscle. Credit score: Harvard SEAS.

To create the FIG ink, Choi leveraged a rotary jet spinning method developed within the lab of Kevin “Package” Parker, Ph.D. that fabricates microfiber supplies utilizing an strategy much like the best way cotton sweet is spun. Postdoctoral researcher and Wyss Lumineer Luke MacQueen, a co-author on the paper, proposed the concept fibers created by the rotary jet spinning method might be added to an ink and 3D printed. Parker is a Wyss Affiliate School member and the Tarr Household Professor of Bioengineering and Utilized Physics at SEAS.

“When Luke developed this idea, the imaginative and prescient was to broaden the vary of spatial scales that might be printed with 3D printers by dropping the underside out of the decrease limits, taking it all the way down to the nanometer scale,” Parker says. “The benefit of manufacturing the fibers with rotary jet spinning relatively than electrospinning” – a extra standard methodology for producing ultrathin fibers – “is that we will use proteins that will in any other case be degraded by {the electrical} fields in electrospinning.”

Utilizing the rotary jet to spin gelatin fibers, Choi produced a sheet of fabric with an identical look to cotton. Subsequent, she used sonification – sound waves – to interrupt that sheet into fibers about 80 to 100 micrometers lengthy and about 5 to 10 micrometers in diameter. Then, she dispersed these fibers right into a hydrogel ink.

“This idea is broadly relevant – we will use our fiber-spinning method to reliably produce fibers within the lengths and shapes we would like.”

– Suji Choi

Probably the most troublesome side was troubleshooting the specified ratio between fibers and hydrogel within the ink to keep up fiber alignment and the general integrity of the 3D-printed construction.

As Choi printed 2D and 3D buildings utilizing FIG ink, the cardiomyocytes lined up in tandem with the route of the fibers contained in the ink. By controlling the printing route, Choi might due to this fact management how the guts muscle cells would align.

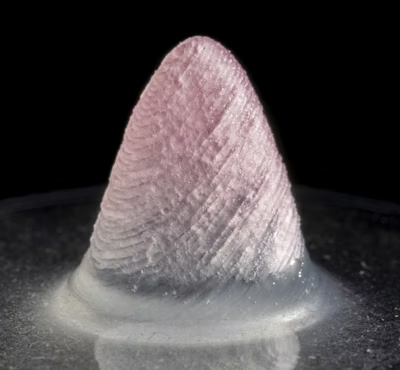

The tissue-engineered 3D ventricle mannequin. Credit score: Harvard SEAS

When she utilized electrical stimulation to 3D-printed buildings made with FIG ink, she discovered it triggered a coordinated wave of contractions in alignment with the route of these fibers. In a ventricle-shaped construction, “it was very thrilling to see the chamber truly pumping in an identical technique to how actual coronary heart ventricles pump,” Choi says.

As she experimented with extra printing instructions and ink formulation, she discovered she might generate even stronger contractions inside ventricle-like shapes.

“In comparison with the actual coronary heart, our ventricle mannequin is simplified and miniaturized,” she says. The crew is now working towards constructing extra life-like coronary heart tissues with thicker muscle partitions that may pump fluid extra strongly. Regardless of not being as robust as actual coronary heart tissue, the 3D-printed ventricle might pump 5-20 instances extra fluid quantity than earlier 3D-printed coronary heart chambers.

The crew says the method can be used to construct coronary heart valves, dual-chambered miniature hearts, and extra.

“FIGs are however one software we now have developed for additive manufacturing,” Parker says. “We’ve got different strategies in improvement as we proceed our quest to construct human tissues for regenerative therapeutics. The objective is to not be software pushed – we’re software agnostic in our seek for a greater technique to construct biology.”

Further authors embrace Keel Yong Lee, Sean L. Kim, Huibin Chang, John F. Zimmerman, Qianru Jin, Michael M. Peters, Herdeline Ann M. Ardoña, Xujie Liu, Ann-Caroline Heiler, Rudy Gabardi, Collin Richardson, William T. Pu, and Andreas Bausch.

This work was sponsored by SEAS; the Nationwide Science Basis by way of the Harvard College Supplies Analysis Science and Engineering Middle (DMR-1420570, DMR-2011754); the Nationwide Institutes of Well being and Nationwide Middle for Advancing Translational Sciences (UH3HL141798, 225 UG3TR003279); the Harvard College Middle for Nanoscale Methods (CNS), a member of the Nationwide Nanotechnology Coordinated Infrastructure Community (NNCI) which is supported by the Nationwide Science Basis (ECCS-2025158, S10OD023519); and the American Chemical Society’s Irving S. Sigal Postdoctoral Fellowships.

Wyss Institute

makes use of Nature’s design ideas to develop bioinspired supplies and gadgets that can rework drugs and create a extra sustainable world.

Wyss Institute

makes use of Nature’s design ideas to develop bioinspired supplies and gadgets that can rework drugs and create a extra sustainable world.

[ad_2]